Description:

NC300-2518 hydraulic die spotting press is mainly used in adjusting and maintenance of plastic mold and hardware molds. Its spotting force reaches 300T and working bench 2500×1800. It absorbs essence of the same product at home and abroad which takes a lot of tine. Automatic NC300-2518 hydraulic die spotting press initiates a revolution in mold industry as it replaces the traditional fitting form of knocking by copper bar, which greatly improves efficiency and precision.

Types of die spotting machine:

300T Disk300T Pressure Plate

Features:

1. Core hydraulic pressure source confirms the operation of each hydraulic cylinder equipped onto metal die.

2. Security guarantee

Installing sensors on the front and back side of hydraulic die spotting press will prevent accidents caused by carelessness and mistakes.

3. Installing a mobile block can prevent metal die falling down when inverted.

4. Low energy consumption

NC300-2518 hydraulic die spotting press greatly reduces energy consumption and exhaust heat compared with traditional methods through inverter control of the main electric motor.

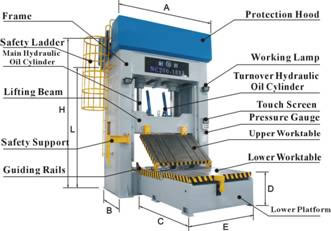

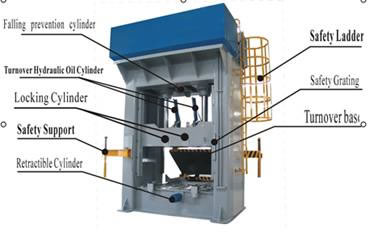

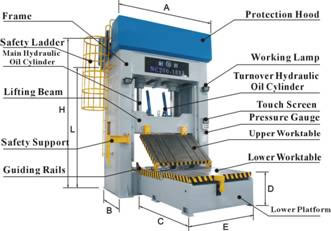

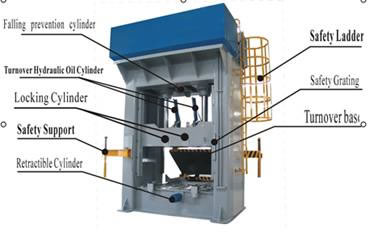

Components of hydraulic die spotting press:

Front view

Front view Side view

Side view

Parameter:

|

Model

|

NC300-2518 hydraulic die spotting press

|

|

Max spotting force(T)

|

300

|

|

Max lifting force(T)

|

80

|

|

Die opening space(mm)

|

2100

|

|

Size of working bench(mm)

|

2500×1800

|

|

Bearing capacity of upper working bench(T)

|

10

|

|

Bearing capacity of lower working bench(T)

|

25

|

|

Suction force of upper magnetic disk(T)

|

245

|

|

Suction force of lower magnetic disk(T)

|

80

|

|

Fast up/down speed(mm/s)

|

70/80

|

|

Slow up/down speed(mm/s)

|

25

|

|

Eject capacity(T)

|

12

|

|

Eject stroke(mm)

|

200

|

|

Out stroke of lower working bench(mm)

|

4000

|

|

Motor power(KW)

|

22

|

|

Total height of machine(H)(mm)

|

7040

|

|

Land area of machine(mm)

|

7300×6200

|

|

Weight of machine(T)

|

55

|

If you need more information about vertical die spotting machine, please click Quick links:

Inspection Method of Die Spotting Machine | Work Flow of Die spotting press

Front view

Front view Side view

Side view