Injection Molding Machine Rapid Die-Change System

Description:

The quick die-change system is widely applied in injection molding machine, which avoids the disadvantages traditional injection dieing machine, like long-time clamping, complicated operation and insecurity. The quick die-change system adopts electric magnetic chuck as fixed template and active template, which can realize clamping and die change in three minutes by simple magnetization and demagnetization. The quick die-change system can be installed in new injection molding machine, then it can be on sale as standard device. Or it can be used to update traditional injection molding machine. Then the traditional molding machine is able to realize die change in three minutes without changing original machine structure, which is practical and convenient.

Features:

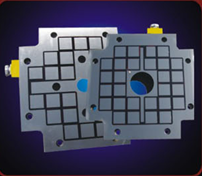

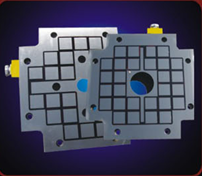

1. Easy installation

It is easy to install quick die-change system neither changing machine structure nor making a hole in the machine. You just need to fix die change system on threaded hole in backboard or T-shape slot by means of bolt.

2. Safety

It is safe and secure. Die change system just needs very short time of magnetization and demagnetization to change die. During working, there is no need for power supply. The strong magnetic force will continue to work even if light is out. Besides, magnetic force won’t become weak or disappear because of time or temperature, which is safe and economical.

3. High efficiency

The quick die-change system can greatly reduce die-change time. It takes 3minutes to change die for the ordinary injection molding machine, 10 minutes for large-scale molding machine to change die.

4. Thickness of the chuck is 5-6cm , covering small area, which won’t occupy mold opening space.

5. It is easy to operate the system. Non-professional person can do it well after one-minute training.